Renewal Energy Important Study Content

Renewal Energy Important Study Point

1.Hemispherical Solar Distillation Unit

| Use |

To produce distilled water |

| Capacity |

3 liters / day |

| Salient features |

- No fuel, Utilize Solar thermal energy.

- Pollution free.

- Simple and easy to install.

|

2.Solar Water Heating System

| Usages |

| Domestic |

Bathing, Coffee / Tea preparation, Dishwashing etc. |

| Industrial |

Pre-heating of boiler feed water, cooking / dishwashing in industrial canteens. washing of milk canes in dairies, sterilisation of surgical instruments etc. |

| Economics (Tentative) |

- A 100 lpd domestic solar water heating system (SWHS) can cater to a family of 5 persons and costs about Rs.20000.

- A 1000 lpd industrial system would cost about Rs.2.0 lakhs and would have a payback period of 2 years.

- It saves about 1500 units of electricity per annum equivalent to about Rs.5000/- per year

|

| General Information |

- Solar water heating system (SWHS) has three main components, namely, Solar Collector, Insulated hot water storage tank and Cold water tank with required insulated hot water pipelines and accessories.

- In the case of smaller systems (100 – 2000 litres per day), the hot water reaches the user end, by natural (thermo – siphon) circulation for which the storage tank is located above the collectors.

- In higher capacity systems, a pump may be used for forced circulation of water. A bank of collectors can be arranged in a series – parallel combination to get higher quantity of hot water.

- A typical 100 litres insulated tank with a 2 m2 collector area, will supply water at a temperature of 60 – 80°C.

- The tanks are generally made of stainless steel to avoid corrosion and are insulated to reduce heat losses.

|

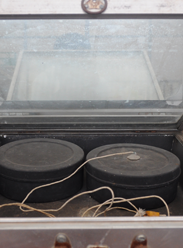

3.Solar Distillation Plant

| Function |

Converting salt water into potable water |

| Specification |

| Area |

15 m2 |

| Concrete |

1:5:10 |

| Wearing coat |

1:1.5:3 (7.5 cm thick black coated) |

| Side walls |

Brick masonry |

| Distilled water collecting channel |

Aluminium |

| Tank |

Two numbers in brick masonry structure |

| Cost of operation |

Rs.6/h |

| General Information |

- The unit is a basin type solar distillation plant of masonry construction, with a basin area of 15 m2 & slope of the glass cover is 15°.

|

| Salient features |

- The still can yield 3 to 4 liters of distilled water per square meter area of the basin in a day.

|

4.Step type Solar dryer

| Function |

Drying of fruits, vegetables and agricultural commodities |

| Specification |

| Collector area |

2.4 x 1.8 m |

| Number of trays |

10 in five steps |

| Insulation (Bottom) |

Glass wool, 10 cm. thick |

| Motive power |

Natural convection |

| Cost of the unit (approx) |

Rs.15000/- |

| Cost of operation |

Rs.3.75/h. |

| General Information |

- Step type solar dryer has a collector area of about 4.32 m2.

- This multi track step type dryer can hold 10 aluminium trays at a time.

- The absorber is 20 gauge GI sheet, black painted at the top with bottom insulation.

|

| Salient features |

- Solar drier takes 40 hours for drying 50 kg of papaya leather, while conventional sun drying takes 61 hours. Thus there is a saving of 21 hours which is 35% when compared to conventional drying.

- The drier handles 10 kg of cocoon per batch and each batch takes 30-40 minutes for completion of stifling. 80 kg of cocoon per day in 8 batches can be conveniently stifled in a day.

|

Renewal Energy Important Study Content

5.Solar Tunnel Dryer for Agro Industrial Applications

| Function |

Natural convection walk-in type dryer for bulk drying of agricultural & agro industrial products at moderate air temperature. |

| Specifications |

- Semicylindrical shaped tunnel with a base area of 3.75 m x 18 m for capacity of 1 ton per batch for drying of sago and coconut Metallic frame structure of tunnel dryer is covered by UV stabilized semi transparent polythene sheet of 200 micron thickness.

- Length of the dryer depends upon type and quantity of the product to be dried per batch. A slope of 10-15o is provided along the length of the tunnel.

|

| Cost (approx) |

Rs 1, 20,000 for standard size (3.75m x 18.0m) |

| Salient features |

- Maximum mean temperature obtained inside the dryer is 57° C while the ambient temperature was 33.5 °C.

- The drying time for sago drying in solar tunnel dryer is 5 h ours with 20% cost saving when compared to open sun (11 hours drying time) method.

- Payback period is 5.8 years for sago product.

- The savings in drying time using coconut as produce is 16 hours, with 42 % cost saving when compared to open sun drying method.

- This tunnel dryer can also be useful for drying of chillies.

|

| Configuration |

- SPV (Solar PhotoVoltaics) lantern is a portable lamp.

- It consists of SPV module of 10 Wp capacity, rechargeable battery, Compact Fluorescent lamp (CFL) of 5 / 7 W and electronics (i.e. inverter and charge controller ).

- When sunlight falls on the SPV module, it is converted into DC electricity, which is stored in a battery and converted into AC electricity by the inverter and used for supplying power to CFL.

- If charged regularly, it can be used for 4 hours daily.

|

| Potential for use |

| Individuals |

Remote households, farm operations, emergency (portable) lamp, fly catchers etc. |

| Industries |

Emergency lamps in factories, offices, canteens, security gates etc. |

| SHGs |

Lanterns may be provided to vendors on hire (daily) by Self Help Groups or small entrepreneurs. |

| Cost |

Rs.3000 (tentative) |

7.Solar Photovoltaic (SPV) Street Lights

| Configuration |

- SPV street lighting system is a stand-alone system consisting of 74 W module, rechargeable battery, CFL lamp of 11 W, electronics (inverters & charge controller)

|

| Potential for use |

| Individuals |

Garden / security lights (compound wall) |

| Industries |

Campus / factory lighting approach road, garden lighting, parking areas, security lights, storage yard etc. |

| Local bodies / Institutions |

Street lights, parks, play fields, bus stands, bus shelters, petrol bunks, resorts etc. |

| Cost |

Rs.25,000/- to Rs.35,000/- depending upon period of warranty. |

8.Solar Water Pumps

| Function |

Drinking water supply for small habitations |

| Specification |

| Type |

DC Surface & AC submersible |

| Capacity of DC Surface |

900 Wp – 1 Hp & 1800 Wp – 2 Hp |

| Capacity of AC submersible |

1800 Wp – 0.75 Hp |

| Water Level Depth (maxi) of DC Surface |

14 meter |

| Water Level Depth (maxi) of AC submersible |

50 meter |

| Discharge Rate of 1 Hp Capacity of DC Surface |

75 000/ day (litres) |

| Discharge Rate of 2 Hp Capacity of DC Surface |

1 40 000/ day (litres) |

| Discharge Rate of AC submersible |

50000/ day (litres) |

| Collector area |

2.4 x 1.8 m |

| Type |

Step type |

| Number of trays |

10 in five steps |

| Insulation (Bottom) |

Glass wool, 10 cm. thick |

| Motive power |

Natural convection |

| Salient features |

- Drinking water supply for small habitations

- Horticulture farms, orchards, vineyards, gardens and nurseries

- Agro forestry and plantations

- Dairy, poultry and sheep farm

- Aqua culture, fish farming

|

Renewal Energy Important Study Content

9.Solar Box Type Cooker

| Function |

For cooking purposes where sunshine is available in plenty |

| Specification |

| Type |

Box type |

| Overall dimensions L x B x H (mm) |

500 x 500 x 200 |

| Weight |

12 kg |

| Time taken in cooking |

35-40 min |

Conversion efficiency for

Rice |

45-60 % |

Conversion efficiency for

vegetables

|

60-100 % |

| Salient features |

- A large number of items such as pulses, rice, kheer, khichri, vegetables, meat, fish etc. can be cooked in the solar cooker.

- The time taken to cook will depend upon the type of food, time of the day and solar intensity.

|

10.Wood Based Down Draft Gasifier

| Function |

For converting Fuel wood to fuel |

| Specification |

| Capacity |

58 kW |

| General Information |

| Fuel consumption |

20 to 25 kg/h |

| Gas production rate |

50 m3/h |

| Thermal output |

500000 kcal/h |

| Cost of the unit (approx) |

Rs.1,50,000/- |

| Salient features |

- Fuel wood can be used as fuel

- 40% fuel saving due to higher thermal efficiency

- No smoke

- Best suited for processing industries with steam

- Fulfill the heat energy requirement in rice mills, turmeric and arecanut processing units etc.

|

11.Deenabandhu Model Biogas Plant

| Function |

Household cooking, lighting and running engines |

| Specification |

| Components |

Dome, Digester, Gas storage, Gas Outlet Pipe, Inlet and out let pipe |

| Feed material |

cow dung, pig manure, poultry droppings etc. |

| Shape of the plant |

Dome model |

| General Information |

- The entire plant is built with brick in cement mortar. Unlike janta Biogas plant it does not require any shuttering, thus reducing the cost of construction.

- The hydraulic retention time for this design is 40 days for northern plains of the country. For hilly regions the retention time is about 50 days.

|

| Salient features |

1- 4 cum capacity in 1 to 2 days duration. |

12.Community Biogas Plant

| Function |

Cooking, lighting and running engines |

| Specification |

| Gas volume |

35 m3 |

| Gas holder height |

1.0 m |

| Inlet/outlet opening |

2.0 x 1.2 m |

| Initial dung required |

32 to 36 tonnes of cowdung |

| Daily loading rate |

800 to 900 kg |

| No. of cattle required |

80 to 90 animals |

| Cost of the unit (approx) |

Rs. l,50,000/- |

| Cost of operation |

Rs. l 00/day |

| General Information |

- The community level biogas plant will be constructed in a common place, the feed material will be collected from a group of households and the produced biogas will be distributed to all the beneficiaries.

|

| Salient features |

- Rate of biogas production :1.5 m3/h

- No. of hours 5 hp dual fuel engine can run: 14 h

- Electricity production potential : 40 kWh

- No. of beneficiaries for Cooking gas : 40 – 50

families

|

Renewal Energy Important Study Content

13.Biodiesel Manufacturing Plant

| Function |

Production of biodiesel from vegetable oils |

| Specification |

| Capacity |

250 kg oil/day |

| Command area required |

25 ha |

| Biodiesel production |

250 L/day |

| Glycerol production |

55 kg/day |

| General Information |

- Biodiesel is produced from Jatropha oil by converting the triglycerides into methyl esters with a process known as transesterification.

|

| Salient features |

- About 250 litres of biodiesel can be produced per day from vegetable oils or tree seed oils.

- Glycerol (by-product), can be used further in soap making or in chemical industries.

|

Renewal Energy Important Study Content

| More Agriculture Engineering Study Material |

Open |

| More Agriculture Study Material |

Open |

| Premium Study Material & Test Series |

Open |